Power factor correction systems

Regulated reactive current compensation

The controlled compensation system multicab regulates reactive power that oscillates back and forth between the generator and consumer without any useful effect in the case of alternating or three-phase current. This targeted control not only reduces the load on your cables, fuses and transformers, but also minimizes their losses. It makes an active contribution to considerable savings in energy costs, contributes significantly to the reduction of CO2 and ensures that you comply with the cosPhi specified by the grid operator (technical connection conditions).

Saving

energy costs andCO2

Compliance with the specifications

of the network operator

Relief of the

Network infrastructure

Customized solutions: from individual planning to high-quality production

Our automatically controlled power factor correction systems are planned, designed and manufactured precisely to your requirements. The system cabinets have a temperature-controlled ventilation system that ensures optimum cooling and prevents damage to appliances due to overheating. In addition we rely exclusively on type-tested quality components. Our capacitors are among the most durable and safest you can get anywhere in the world. The secureC safety and maintenance module and the automatic extinguishing system also set new standards. Safety is a top priority for us!

Thanks to our convenient modular design, system expansions can be implemented quickly and easily. All system modules are flexible and fit seamlessly into almost any cabinet system. Rely on customized solutions for your individual requirements. All compensation systems are available choked or unchoked.

Why is reactive power compensated?

Power factor correction systems are used to reduce reactive energy costs.

In addition, electrical equipment such as cables, switching devices, transformers or generators are relieved of reactive power through compensation. In the best case scenario, this will save you the cost of a new supply line or the purchase of a new transformer. This allows you to use your own generation systems more economically and purchase as little external energy as possible.

What is reactive power?

Reactive power is the power required by inductive loads such as motors, transformers, ballasts, induction furnaces, etc., i.e. coils of any design, to generate a magnetic field. The reactive power is also referred to as magnetizing power. It oscillates between the consumer and the generator (energy supplier) at twice the mains frequency. The reactive power places a load on the cables, transformers and fuses.

It is precisely this burden that energy suppliers have to pay for via the electricity bill.

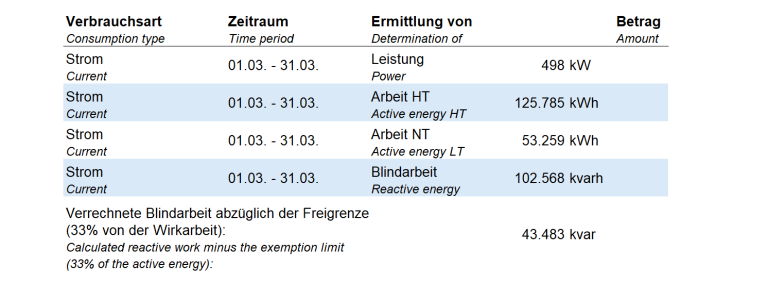

Example based on a sample electricity bill

This company had a maximum power consumption of 498 kW. The company purchased the active energy at a high and a low tariff time (HT and LT). The total active energy consumption amounted to 179,044 kWh.

According to the energy supply tariff, 33 % of the active energy may be drawn free of charge as reactive energy, which corresponds to 59,084 kvarh. If this value is subtracted from the total reactive energy, the amount shown in the table is 43,483 kvarh.

If this company were located in Hamburg and purchased energy from Vattenfall via the municipal utilities of the Hanseatic city, it would have to pay 1.55 cents per kvarh to the energy supplier, which amounts to an annual sum of around €8,087.

Amortization period

For operation with a higher output or operating time, there is naturally a correspondingly higher savings potential.

As a result, the amortization times of newly installed compensation systems vary. Based on our example above, we assume an amortization period of around two years.

Products & Solutions